What is concrete?

Concrete is a mixture which is composed of materials like cement, fine aggregates (sand) and coarse aggregates mixed with water which hardens with time.

Concrete is the main material for 90% of construction works.

There are many types of concrete based on the the materials used in the mixture during manufacturing process of concrete.

Related article: What is Green Concrete? Advantages | Disadvantages | Properties

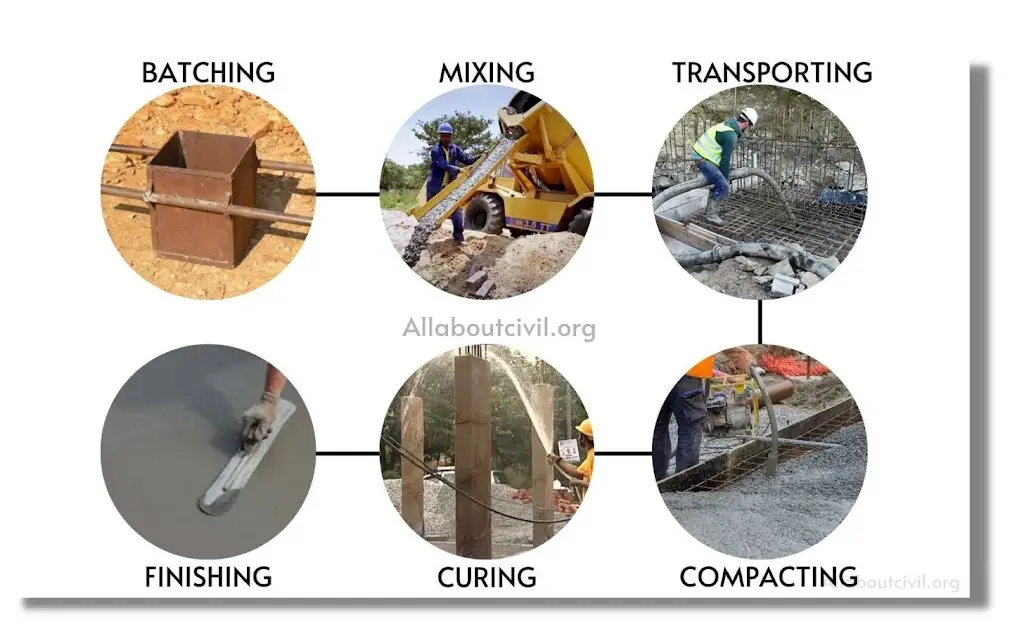

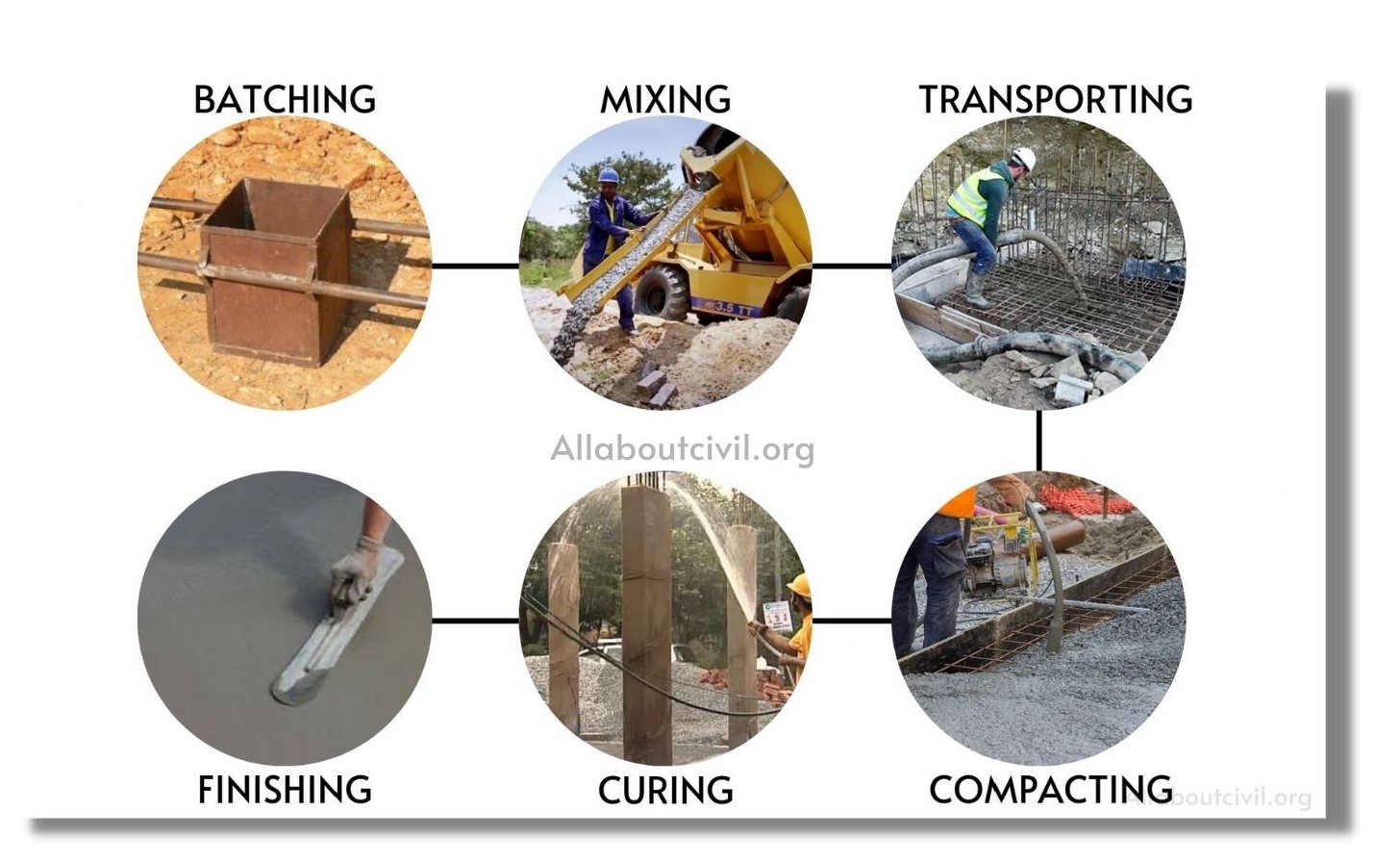

Manufacturing process of concrete

● BATCHING

● MIXING

● TRANSPORTING

● PLACING

● COMPACTING

● CURING

● FINISHING

Batching

Batching is the process involves in measuring concrete mix ingredients by either mass or volume and pouring ingredients into the mixer. To produce a uniform quality concrete during manufacturing process, the ingredients must be measured accurately for each batch.

There are two types of batching

1. Volume batching

2. Weight batching

Volume batching

● This method is generally adopted for small jobs.

● Gauge boxes are used for measuring the fine and coarse aggregate.

● The volume of gauge box is equal to the volume of one bag of cement.

● Gauge boxes are also called as FARMAS

● They can be made of timbers or steel.

● They are made generally deep and narrow

● Bottomless gauge boxes are generally avoided.

● The material should be filled loosely in the gauge boxes, no compaction is allowed.

Weigh Batching

Batching by weight is more preferable in manufacturing of concrete than volume batching ,as it is more accurate and leads to more uniform proportioning of concrete.

● Weigh batching does not have uncertainties associated with bulking.

● It’s equipment falls into 3 general categories :

I. Manual,

II. Semi automatic

III. Fully automatic

1. Manual – In manual batching all weighing and batching of concrete are done manually and It is used for small jobs.

2. Semi automatic – In this type of batching the aggregate bin gates are opened by manually operated switches. And gates are closed automatically when the material has been delivered.

This system also contains interlock which prevents charging and discharging.

3. Fully automatic – In automatic batching with single switch the material are electrically activates and complete autographic record are made of the weight of each material.

The batching plant comprises 2, 3, 4 or 6 compartment bins of various capacities. Over the conveyer belt the weigh batchers discharging are provided below the bins

Mixing

During manufacturing process the mixing of concrete should ensure that the mass becomes Homogeneous , uniform in colour and consistency.

Methods of Mixing :

• Hands(using hand shovels)

• Stationary Mixers

• Ready mix concrete

Hand Mixing

Mixing ingredients of concrete by hands using ordinary tools like, hand shovels etc. This type of mixing is done for Less output of concrete.

Stationary Mixers

Concrete is sometime mixed at jobsite in a stationary mixer having a size of 9 cubic meters.

Ready Mixed Concrete

Ready mixed concrete is proportioned and mixed off at the project site and is delivered to the construction area in a freshly mixed and unhardened state.

It can be manufactured by any of the following methods:

1. Central-mixed concrete

2. Truck-mixed concrete

Transporting and Placing

● Mortar Pan : Concrete carried in small Quantities

● Wheelbarrows and Buggies : Short flat hauls on all types of onsite concrete construction

● Belt Conveyors: Supplying concrete horizontally or higher/lower level.

● Cranes and Buckets: Used for Work above ground level, Buckets use with Cranes, cableways, and helicopters.

● Pumps: supplying concrete from central discharge point to formwork.

● Transit Mixer: used for long distance transporting the concrete particularly in RMC plant

Compaction of concrete

● Compaction of concrete is process that helps in expelling the trapped air from the concrete

● During the process of mixing, transporting and placing of concrete air is likely to get trapped in the concrete.

● Studies say that 1% air in the concrete can approximately reduces the strength of concrete by 6%.

● If air is not expelled from concrete, it will result in forming honeycombs and reduced strength.

Different Methods of Concrete Compaction

1) Hand Compaction – Rodding, Ramming, Tamping

2) Compaction by Vibration – Internal vibrator, Formwork vibrator, Table Vibrator, Platform vibrator, Surface vibrator.

Curing

Curing of freshly placed concrete is very important for optimum strength and durability. The process of keeping concrete damp for this purpose is known as curing.

The object is to prevent the loss of moisture from concrete due to evaporation or any other reason.

Curing must be done for at least three weeks and in no case for less than ten days. There are many types of curing methods which can be adopted based of requirements.

Finishing

The reason Concrete is used because of its high compressive strength. However, the finish of the ultimate product is not that pleasant. In past couple of decades efforts have been made to develop surface finishes to give a better appearance to concrete surfaces and are as follows.

1. Formwork Finishes

2. Surface Treatments

3. Applied Finishes

Also Read: What is fiber reinforced concrete?| Types of Fibers | Properties |Uses