|

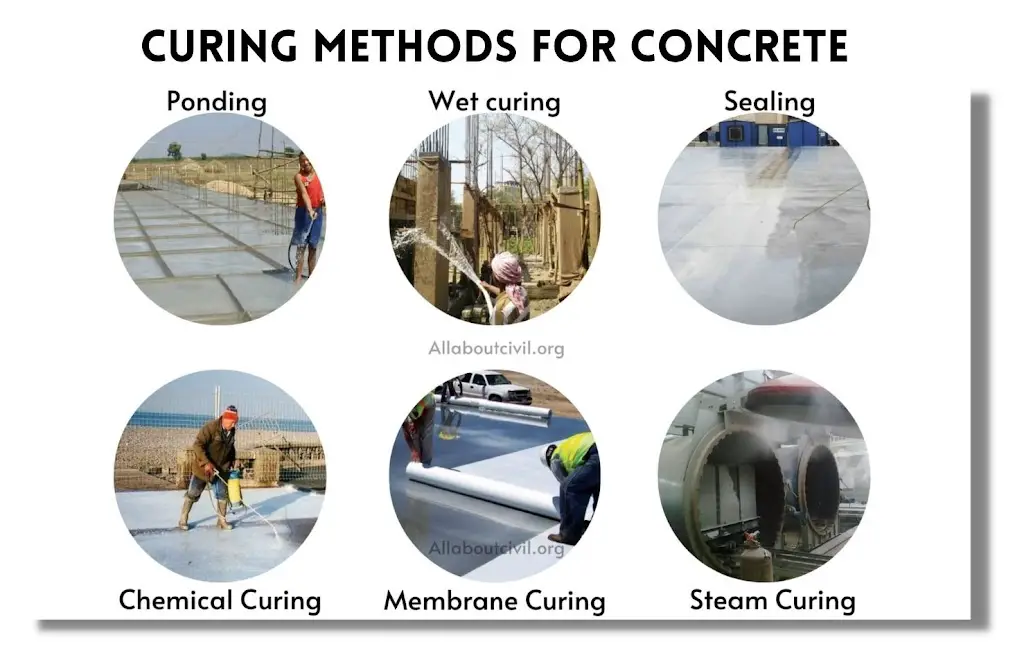

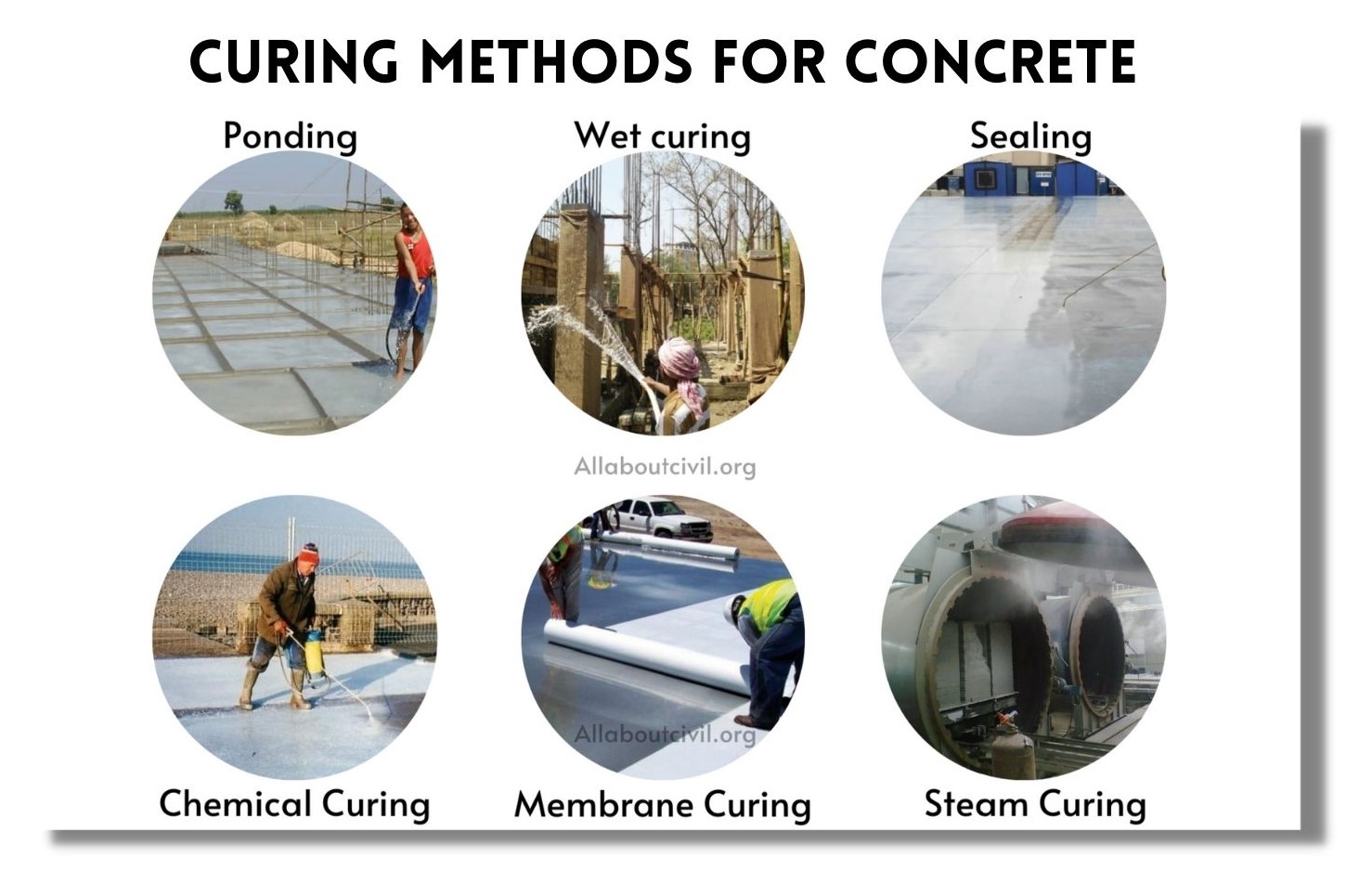

| Image-Types of curing methods for concrete |

What is Curing in concrete?

Curing is a process of maintaining the concrete’s moisture and temperature till it completes hydration process or till it attain particular strength.

Why curing of concrete is done?

When the water is added to the concrete mixture hydration(reaction b/w cement and water) process takes place, which tends to dry up the concrete quickly.

In order to stop concrete from drying out, Curing of concrete is done for a particular period of time to keep the concrete moist till it attain its maximum strength.

Curing helps concrete in increasing it’s durability and impermeability and reduces the shrinkage.

Also Read: What is Green Concrete? Advantages | Disadvantages | Properties

What is curing period of concrete?

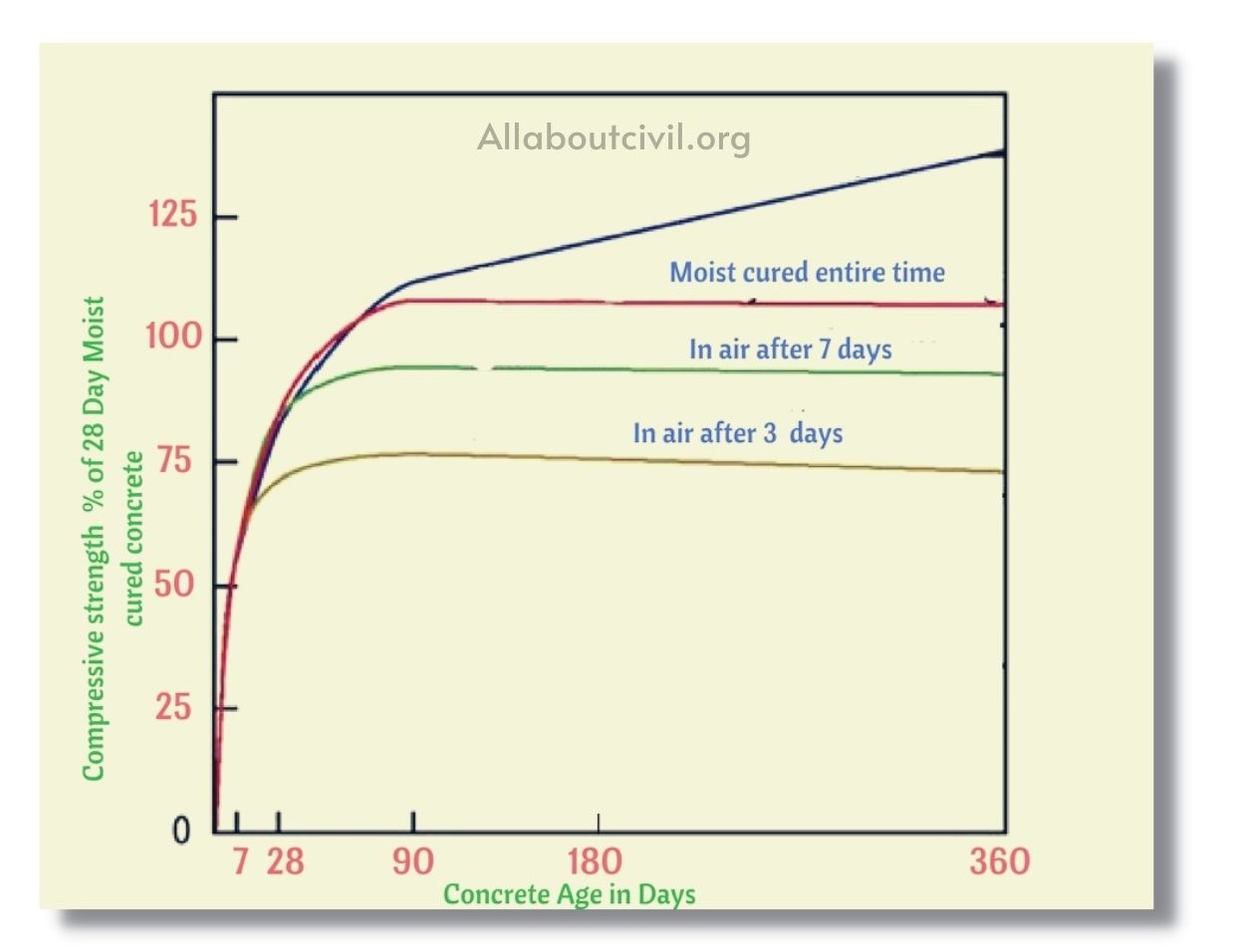

As per the graph show above, it is clear to say that concrete attained 50% of its design strength when it cured for a period of 3-7 Days. 75% of Compressive strength achieved in period of 14 days. 90% of Concrete design strength achieved in 28 days. So with this data we can clearly say as time increases on the concrete strength increased.

- Shape and size of the concrete member

- Concrete Grade

- Temperature

- Design Strength or Specified strength of concrete

Types of curing methods for concrete

● Ponding method

● Gunny Bags Curing or wet curing

● Sealing Curing Compounds

● Chemical Curing

● Membrane Curing

● Steam Curing

Water Ponding

The water ponding curing method is a widely used and efficient method to cure the concrete.

In this method the surface is divided into a small water holding portions in from of rectangular shapes which are filled with water.

This method is generally used for flat surfaces like curing concrete slabs and pavements.

Gunny Bags Curing or Wet Curing or moist curing

Gunny bags curing are basically used for vertical concrete members, Where the members are covered with gunny bags, and water is sprayed at regulars intervals.

Gunny bags curing are applied to vertical members like column and walls. when water is sprayed at regular intervals, It keeps them moist for long period

Sealing Curing Compounds

As soon as concrete finishing is done, a layer of solvent or water based sealing curing compound is applied to the concrete. which prevents loss of moisture from the concrete and stays moist for longer period.

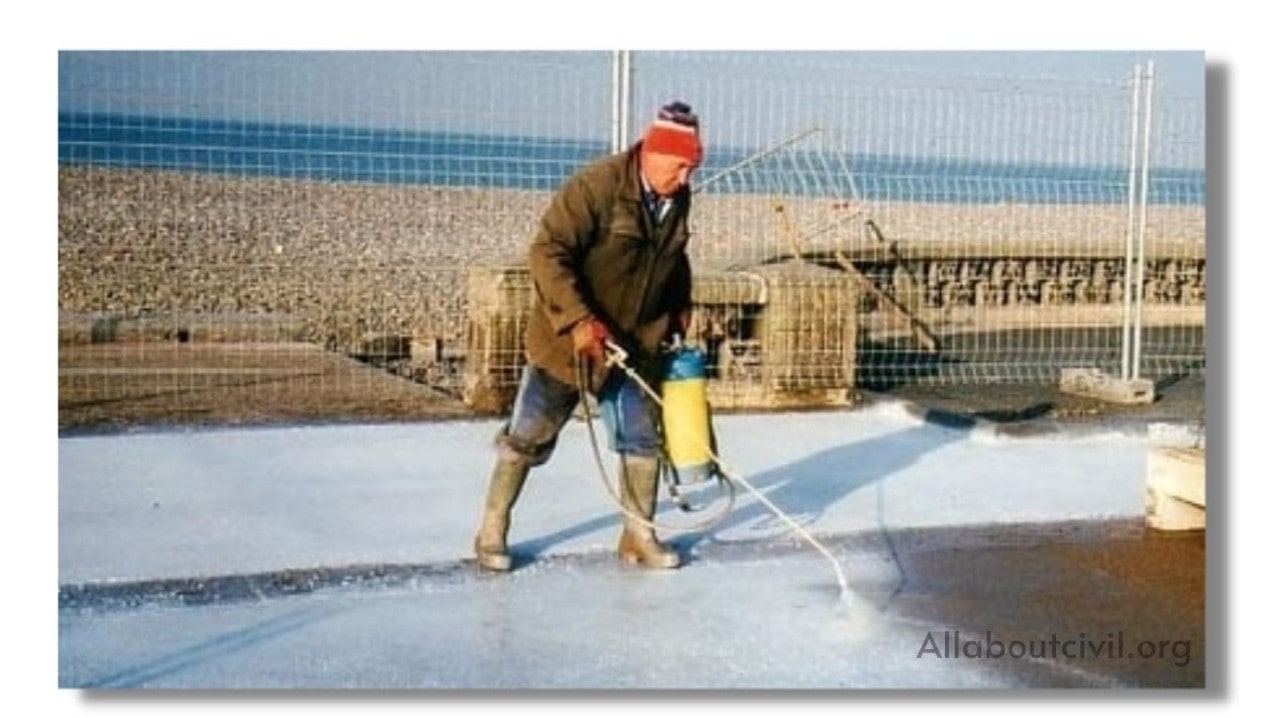

Chemical Curing

The chemical curing of concrete methods applied when curing concrete with water is not possible or their is a water scarcity. In this method, water is added to the hygroscopic material and sprinkled over the surface.

The hygroscopic material absorbs moisture from the atmosphere and keeps the surface damp.

Membrane Curing

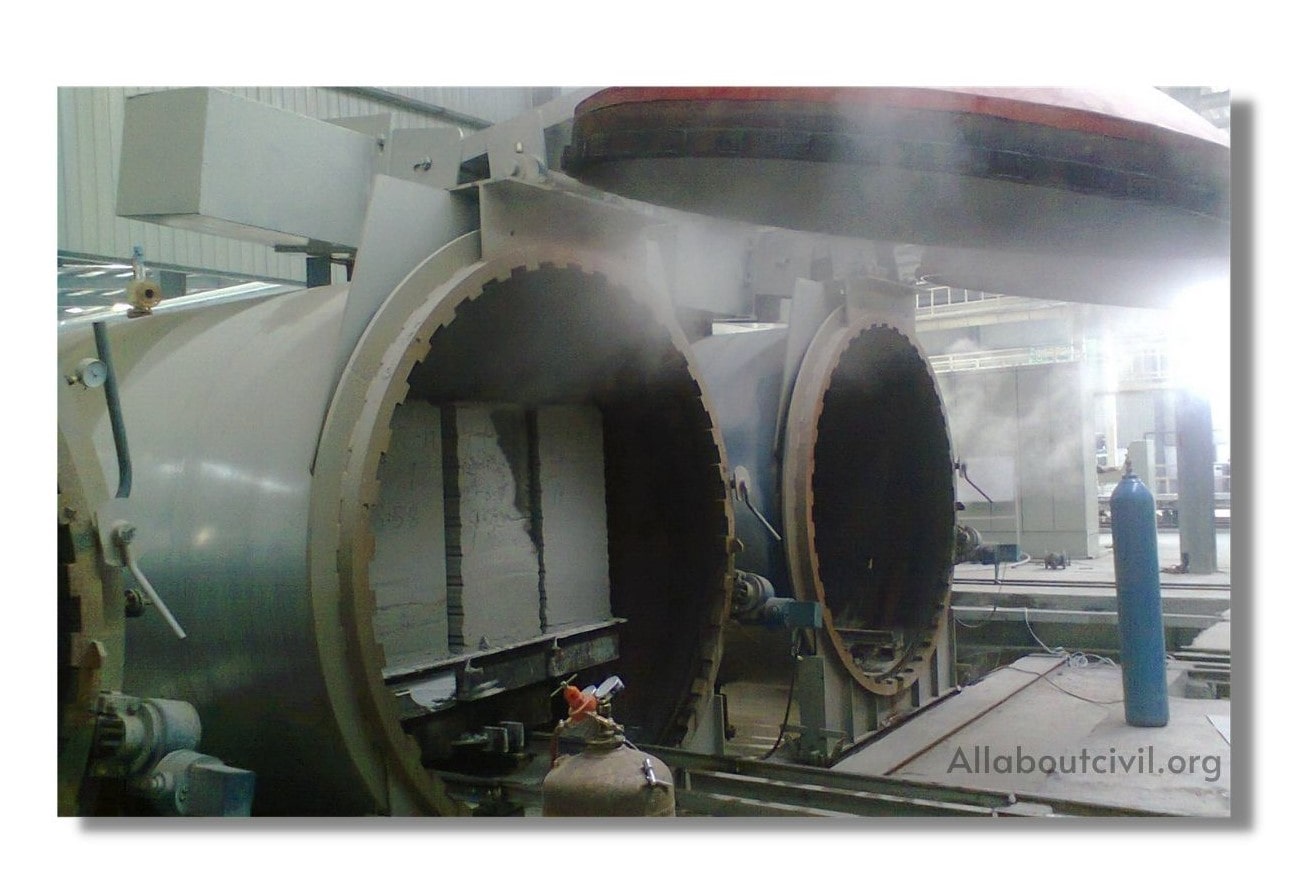

Steam Curing

Curing done by water vapor known as steam curing.

Stem curing is done under 2 conditions such as

1. Under atmospheric pressure

2. Under high pressure

Steam curing helps concrete to gain early strength rapidly. Steam curing will be applied on hardened concrete after 3 hours in a controlled manner. The precast concrete element is often cured by steam pressure.

Also Read: What is Prestressed Concrete? Advantages & Disadvantages | Applications