Define pointing in construction

Pointing in construction is a term used to define the finishing of mortar joints in stone or brick masonry construction.

Pointing can be defined as a technique or a process of repairing and strengthening brick masonry or stone masonry mortar joints. When the existing mortar joints crack and disintegrate, then the damaged mortar is removed by hand or power tool and replaced with fresh mortar of the same composition as the previous one.

Mortar Used for Pointing Work

- Pointing by Lime Mortar – Lime mortar is prepared by adding 1 part of fat lime and 2 parts of sand.

- Pointing by Cement Mortar- Cement mortar is prepared by adding 1 part of cement and 3 parts of sand.

Methods of Pointing in Construction

Pointing in construction is done in the following method:

- Old mortar from the masonry joints is raked or removed out to a depth of 20mm to achieve great bonding.

- Now clean up the dust and other debris from the joints using wire mesh.

- Now clean the joint with water and keep it wet for an hour.

- Fill the joints with mortar(lime or cement) in the desired shape to fill all joint space.

- Make sure you press the mortar into joints with a trowel, to have strong bonding between old and new mortar surfaces.

- Apply the same method to all vertical and horizontal joints and curing must be done for at least ten days if cement mortar is used or three days if a lime mortar is used.

Related Topic- What is plaster? | Methods | Defects | Materials

Types of Pointing in Construction

Following are the types of pointing in construction:

- Flush Pointing

- Weathered Pointing

- Keyed pointing or Grooved Pointing

- V-Pointing

- Beaded Pointing

- Struck Pointing

- Recessed Pointing

- Tuck Pointing

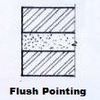

Flush Pointing

In flush pointing, the mortar is pressed hard into the raked joints and finishing off flush with the edge of structural masonry units(Bricks or stones). which gives a smooth appearance, later these edges are neatly trimmed off with a trowel and straight edge.

Though it may result in a bad appearance, still, flush pointing is more durable because it does not allow any provisional space for water, dust, etc. For this reason, flush pointing is widely adopted.

Weathered Pointing

Weathered pointing is a type of pointing in which the mortar is pressed into joints and while the mortar is still fresh the top of the joint is neatly pressed back about 9-6mm with the help of a pointing tool.

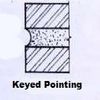

Keyed Pointing or Grooved Pointing

Keyed pointing is a type of pointing in which the mortar is pressed into joints by a sharp trowel and finishing it with the face of the masonry surface.

Then, the horizontal joints are pressed with a steel rod(6mm dia) in the form of an arc or half-circle as seen in the image below. A similar procedure is applied to vertical joints.

Keyed pointing are widely used in a superior type of works, mainly for vertical joints of masonry units.

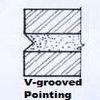

V – Grooved Pointing

V pointing is a type of pointing in which the mortar is pressed in masonry joints and with help of a v-shaped tool a groove is made. V pointing is similar to keyed pointing only a difference in the shape of pointing.

Where v pointing has V shape grooves, while keyed pointing has an arc shape.

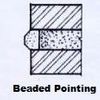

Beaded Pointing

Beaded pointing is a type of pointing in which the mortar is pressed into masonry joints and grooves are made in the concave shape by using a steel rod with a concave shape.

Beaded pointing has a great appearance but it is most likely to get damaged quickly.

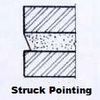

Struck Pointing

Struck pointing is a modification of flush pointing where the mortar is pressed into masonry joints and the top of the joint is pressed inside around 10mm in the form of an inclined shape.

This slope will from top to bottom which helps to drain off rainwater quickly.

Recessed Pointing

In recessed pointing, the mortar is pressed back by 5mm or more from the masonry surface edge. Recessed pointing is not suitable for buildings or walls in an exposed situation as it is difficult to drain off rainwater.

In recessed pointing, the finished face of the pointing mortar is kept back 5mm from the edge. The end result of recessed pointing gives a good appearance.

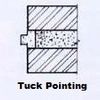

Tuck Pointing

In tuckpointing, the mortar is filled and pressed into masonry joints and flushing with the face. While the mortar is still fresh a groove or a narrow channel is created in the center of the grove with 5mm width and 3mm depth.

This groove is later filled with white cement putty, which is kept towards the face of the joint by 3mm. if this projection is done in a mortar then it is called bastard pointing or half tuckpointing.

Advantages of Pointing in Construction

There are many advantages of pointing in construction, some of them are mentioned below.

- Protects the external wall from rainwater.

- Pointing helps to restore the overall building appearance.

- Pointing helps to reduce any ongoing brickwork maintenance work.

- Pointing helps in achieving the structural integrity of the structure.

- It also increases the value of your property.

Get all types of pointing ppt and keyed pointing notes pdf from our Join our telegram channel

Also Read – Interlocking Bricks | Manufacturing Process of Interlock Bricks