What are Interlocking Bricks?

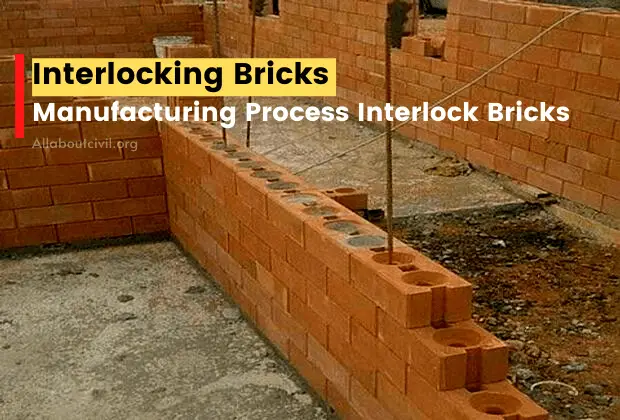

Interlocking Bricks are the enhanced form of conventional clay bricks, interlock bricks are constructively designed to interlock with each other instead of using cement mortar between the bricks.

Interlocking bricks comes in different types of such as interlocking paving bricks, interlock wall bricks, interlocking landscape bricks, interlocking retaining wall bricks etc.

Interlocking Bricks size

Interlock bricks comes in two different sizes such as:

- Full interlock bricks with size of 300 x 150 x 100 mm for all standard walls.

- Half interlock bricks with size of 150 x 150 x 100 mm these are usually made by cutting full interlock bricks in half.

Manufacturing Process Interlock Bricks

Interlocking bricks are made by mixing and compressing cement, sand, and stone dust together in appropriate ratio. The manufacturing process involves following steps.

- First the materials which are required for interlocking bricks are batched and mixed proportionately.

- Then the prepared mix is compressed in a hydraulic compression machine with a desirable interlock pattern to form interlocking bricks.

- Now these compressed bricks are stacked and cured for about 7 days.

- After curing the cement sets and bonds with sand, to form a stabilized interlocking bricks.

Advantages of Interlocking Bricks

- No plaster work – These bricks are designed to minimize the construction time and cost, as plastering can be time consuming process to eliminate it a fair faced bricks are used and a thin coat of paint is applied for smooth finish.

- Cooler Interior – Interlocking bricks are less heat intensive and provides cooler interior.

- No Skilled labors required – Has there is no cement mortar use here, An unskilled or less skilled can lay these interlock bricks.

- Time Efficient – Interlocking bricks requires only 7 days of curing, where as conventional bricks require 28 days of curing hence it reduce the time consuming process.

- Cost Efficient – Interlocking bricks does not require cement mortar for the joints as they can be fixed through interlock patterns thus helps in reducing the construction cost.

Disadvantages of Interlocking Bricks

These are the following disadvantages of interlock bricks

- Interlocking bricks are suitable for load bearing structures, and not suitable for building having more than two stories.

- Entry of rainwater in the line gaps results in change of interlock bricks color.

- These line gaps can also become hostage for insects.

Also Read – Brickwork Calculation Formula

Found Useful, Share with others