What is Activated Sludge Process (ASP)?

Activated sludge process is a type of wastewater treatment, Which can be referred or defined as a biological treatment processes that use a suspended growth of organisms to remove BOD and suspended solids and process requires an aeration tank and a settling tank.

History

The activated sludge process was developed in England in 1913 by Edward Ardern and W.T Lockett was so named as Activated Sludge Process because it involved the assembly of an activated mass of microorganisms that are capable of aerobically stabilizing the organic content of a waste or sewage. Activated sludge process is perhaps the foremost versatile among wastewater treatment process, The biological treatment processes capable of manufacturing an effluent with any desired BOD. The process has thus found wide application among domestic wastewater and industrial wastewater treatment.

Activated Sludge Process Basic Components

1. Primary Clarifier-Which is used to separate solids carried along with Sewage/Effluent.

2. Reactor- Where the microorganisms are kept in suspension, aerated, and in contact with the waste they are treating.

3. Liquid-Which is used for solid separation

4. Sludge recycling system-Which helps in returning activated sludge back to the beginning of the process.

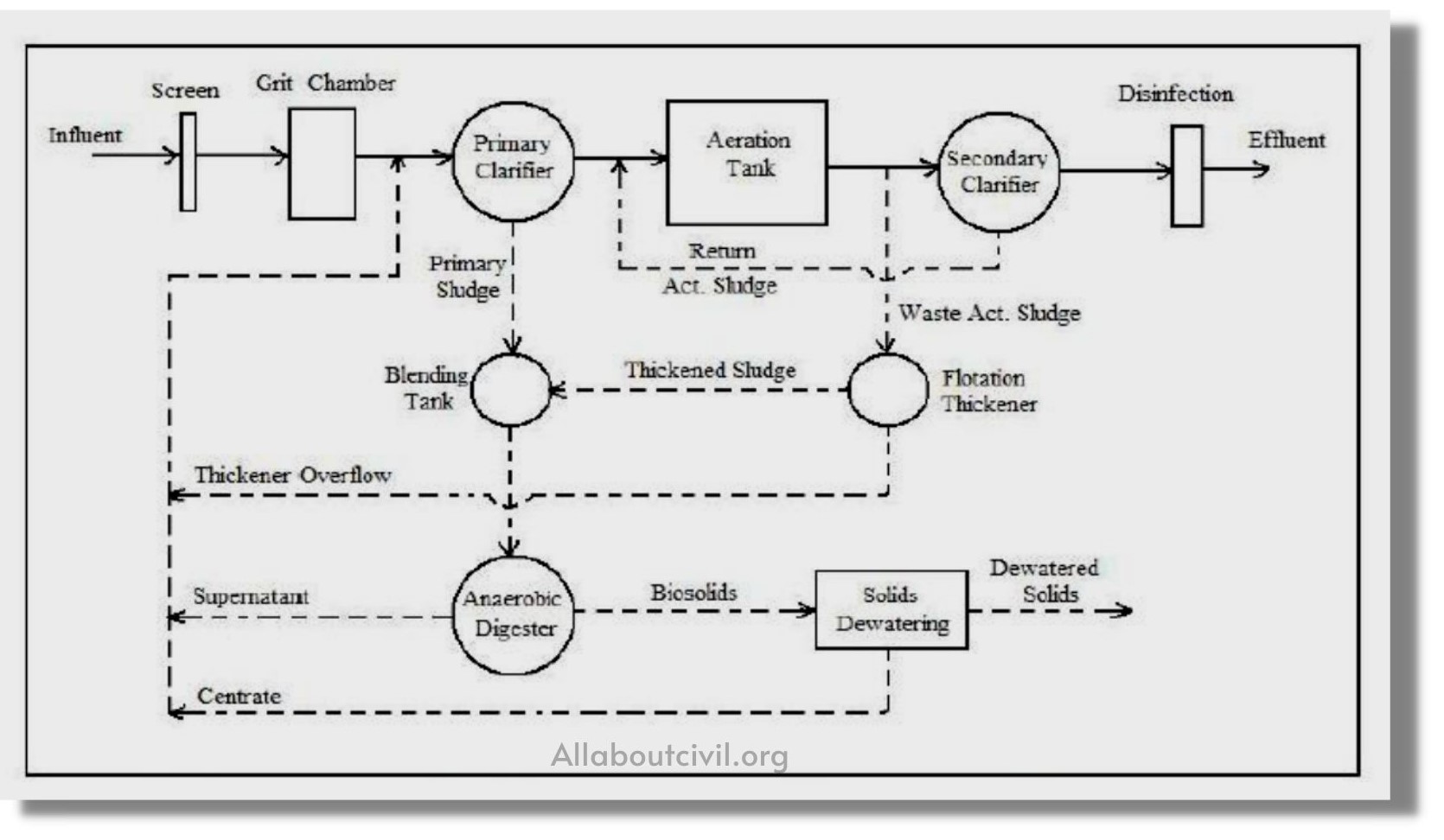

Flow diagram of Activated Sludge Process (ASP)

Activated sludge process Description

Activated sludge process Description

Primary effluent is mixed with return activated sludge to make mixed liquor. The mixed liquor is aerated for a specified length of time/duration. During the aeration, the activated sludge organisms use the available organic matter as food-producing stable solids and more organisms. The suspended solids produced by the method and therefore the additional organisms become a part of the activated sludge. The solids are then separated from the wastewater within the settling tank. The solids are returned to the influent of the aeration tank (return activated sludge). Periodically the excess solids and organisms are removed from the system (waste-activated sludge). Failure to get rid of waste solids will end in poor performance and loss of solids out of the system over the settling tank effluent weir.

Factors affecting Activated Sludge Process (ASP)

There is a variety of things that affect the performance of an activated sludge treatment system. These include:

● Temperature

● Return rates

● Amount of oxygen available

● Amount of organic matter available

● pH

● Waste rates

● Aeration time

● Wastewater toxicity

To obtain the desired level of performance in an activated sludge system, a correct balance must be maintained between the amounts of food (organic matter), organisms (activated sludge) and oxygen (dissolved oxygen).

Also Read: What is sanitary engineering?| Definitions of some common terms

Types of Activated Sludge Process plants

Package plants

These are common variants of extended aeration, to promote the ‘fit & forget’ approach required for small communities or industrial plants without a proper dedicated operational staff. There are various standards to assist with their design.

Oxidation ditch

Oxidation ditches are installed commonly as ‘fit & forget’ technology, with typical design parameters of a hydraulic retention time of 24-48 hours, and a sludge age of 12-20 days. This compares with nitrifying activated sludge plants having a retention time of 8 hours, and a sludge age of 8-12 days.

Deep Shaft

These types of activated sludge plants are used where land is in short supply, sewage may be treated by injection of oxygen into a pressured return sludge stream which is injected into the base of a deep columnar tank buried in the ground. Such shafts may be up to 100 m deep and are filled with sewage liquor.

However, the costs of construction are high. Deep Shaft has seen the greatest uptake in Japan, because of the land area issues.

Surface-aerated basins

The most common biological oxidation processes for treating industrial wastewaters have in common is the use of oxygen and microbial action. Surface-aerated basins achieve 80 to 90% removal of BOD with retention times of 1 to 10 days. These types of activated sludge plant basins may range in depth from 1.5 to 5.0 m and utilize motor-driven aerators floating on the surface of the wastewater.

In an aerated basin system, the aerators provide two functions:

- They transfer air into the basins required by the biological oxidation reactions.

- They provide the mixing required for dispersing the air and for contacting the reactants.

Typically, the floating surface aerators are rated to deliver the amount of air equivalent to 1.8 to 2.7 kg O2/kWh.

However, they do not provide as good mixing as is normally achieved in activated sludge process systems and therefore aerated basins do not achieve the same performance level as activated sludge process units.

Advantages of Activated Sludge Process

1. It gives clear and non-putrescible effluent.

2. The process is free from offensive odor.

3. The process requires limited land area.

4. The sludge has commercial value.

Disadvantages of Activated Sludge Process

1. Activated sludge method requires skilled personnel, careful supervision for design, operation and maintenance.

2. It gives poor results for shock loads and fluctuations in the effluent.

3. the quantity of the sludge produced is large and difficulties arise during the dewatering of sludge.

4. Activated sludge process requires a more initial investment.

Also Read: Methods to Control Evaporation From Lakes