|

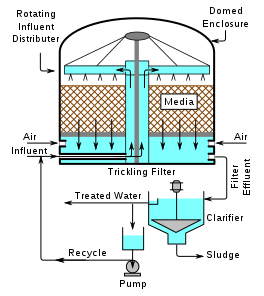

| Image-Trickling filters system |

What is Trickling filters?

Trickling filters are adopted for giving secondary treatment to sewage in wastewater treatment process. trickling filters consists of tanks of coarser filtering medium, over which the sewage is allowed to sprinkle or trickled down by means of spray nozzles or rotary distributors.

The percolating sewage is collected at the bottom of the tank through a well-designed under drainage system. The purification of the sewage is brought about mainly by the aerobic bacteria, which form a bacterial film around the particles of the filtering medium. The action due to the mechanical straining of the filter bed is much less.

In order to ensure the large-scale growth of the aerobic bacteria, sufficient quantity of oxygen is supplied by providing suitable ventilation facilities in the body of the filter and also to some extent by the intermittent functioning of the filter.

The effluent obtained from the filter must be taken to the secondary clarifier for the settling out the organic matter, oxidized while passing down the filter.

Construction and operation of trickling filter

Trickling filter tanks are generally constructed above the ground. They may either be rectangular or more generally circular.

Rectangular filters are provided with a network of pipes having fixed nozzles, which spray the incoming sewage into the air, which then falls over the bed of the filter under the action of gravity.

Circular filter tanks are provided with rotary distributors having a number of distributing arms (generally 4 no’s). These distributors rotate around a central support either by an electric motor or more generally by the force of reaction on the sprays. Such self- propelled reaction type of distributors is now-a-days preferred and used.

The rate of revolutions varies from 2 RPM for small distributors to < ½ RPM for large distributors. Two arms are used for taking low flows and all 4 arms are used in case of high flows. The distributing arms should remain about 15 to 20cm above the top surface of the filtering medium in the tank.

The application of the sewage to the filter is practically continuous with a rotary distributor, whereas with spray nozzles, the filter is dosed for 3 to 5min and then rested for 5 to 10min before the next application. The dosing tanks are used in case of spray nozzles method.

The filtering medium consists of coarser materials like cubically broken stones or slag free from dust or small pieces of stones. The size varies from 25 to 75mm. The filtering material should be washed before it is placed in position and it should be unaffected by acidic action of sewage and should be sufficiently hard. Usually, strong form rocks of granite or limestone may be used. The depth of filtering medium may vary from 2 to 3m. The walls of the filter tank should be provided with openings for the circulation of air through.

The under-drainage system below the filter bed provides drainage and also ventilation of the sewage. These systems are made of vitrified clay blocks which are placed on a concrete thickness of 10 to 15cm thick and which is sloped gently at about 1 in 300 towards the main effluent rectangular channel. The main effluent channel may be provided adjoining the central column of the distributor. The depth and width of this central channel should be such that, maximum flow is carried below the level of the under drains.

Design of trickling filters

Design of tickling filters involves the design of diameter of the circular filter tank, its depth, the design of rotary distributor and under-drainage system.

● Design of trickling filter size is based upon the values of the filter loading – 22 to 44 million liters per hectare per day.

● Organic loading rate – 900 to 2200 kg of BOD5 per ha-m.

With an assumed value of organic loading, we can find out the total volume of the required filter by dividing the total BOD5 of the sewage entering the filter per day in kg, by the assumed value of the organic loading. The organic loading can thus decide the volume of the filter.

The hydraulic loading rate o the other hand gives us the area of the filter required; when the total sewage volume entering the filter per day is divided by the hydraulic loading. Knowing the volume and the area of the cylindrical filter, we can easily find out its dia and depth.

Advantages and Disadvantages of Trickling filter

| Advantages | Disadvantages |

|---|---|

| Efficient nitrification (ammonium oxidation) | Trickling filters Requires expert design and construction, particularly, the dosing system |

| Small land area required compared to constructed wetlands | Trickling filters Requires operation and maintenance by skilled personnel |

| Trickling filters Can be operated at a range of organic and hydraulic loading rates | Trickling filters requires High capital costs |

| Trickling filters are Resistant to shock loadings | Requires a constant source of electricity and constant wastewater flow |

| High effluent quality in terms of BOD and suspended solids removal; in combination with a primary and tertiary treatment also in terms of pathogens | Trickling filters involves in risk of clogging, depending on pre- and primary treatment |