What is a Concrete Mixer?

Concrete mixer is mechanically operating machine which is used to mix cement, aggregates and water to produce homogenous concrete.

There are different types of concrete mixers available which makes concrete production quick and economical than the manual mix.

Related-Ready Mix Concrete-Definition |Advantages | Disadvantages

Types of Concrete Mixers Machine

There are two main types of concrete mixers machine:

1. Batch mixers

2. Continuous mixers

Batch Concrete Mixers

These mixers are widely used for concrete mixing. As the name suggest, Concrete mix obtained by batch mixers is collected batch by batch and time by time. So, it is called as batch mixer. After pouring all the raw materials into mixer. It mixes all of those for some time and finally discharges. This process is repeated until required amount of concrete mix is obtained.

In general Batch mixers are two types.

- Drum type mixers

- Pan type mixers

Drum type mixers

In case Drum type mixers concrete ingredients are mixed in a drum which is actually in double conical frustum shape. Drum types mixers are classified into three types:

● Tilting drum mixers

● Non-tilting drum mixers

● Reversing drum mixers

Tilting Drum Mixers

Discharging of concrete from drum by tilting downwards is know as Tilting drum mixers.

Tilting drum mixers are used for larger projects and where construction work is done intensively. These drum mixers delivers concrete by gravity that is tilting the drum downwards because of this the concrete mix obtained will be not subjected to segregation.

These types of mixers are suitable to obtain concrete with low workability and large size aggregates.

Mixing efficiency depends on some of the factors as follows

● Angle of the drum

● Shape of the drum

● Size of blades

● Angle of blades

The only drawback of tilting drum mixer is sticking of concrete to bottom of drum. To overcome this a method called buttering of mixer is applied in which some amount of cement mortar is mixed in the mixer before mixing first batch of concrete.

Non-Tilting Drum Mixers

These type of mixers are not allowed to tilt and mixer drum rotates about its horizontal axis. After mixing the discharge of concrete is done through a chute which is in inclined position. The drum consist of two open ends and consists blades inside the drum which helps in mixing the materials that are poured through one end and concrete mix is discharged out through other end.

In non-tilting drum mixers, Rapid discharge of concrete is not possible. Due to this delay, concrete may be vulnerable to segregation. This type of mixer is not suitable for large size aggregates as the mix cannot be discharged easily. Non-titling drums mixers are generally used for small projects.

Reversing Drum Mixers

Reversing drum mixers are similar to non-tilting type mixers but in this case reversal of rotation takes place for different action. The drum has two openings, one end is for pouring materials and other end is for discharge of mix. The drum rotates about its horizontal axis. The rotation of drum takes place in one direction for mixing and in opposite direction for discharging. Two different set of blades are arranged for mixing and discharging. They are suitable for dry concrete mixes.

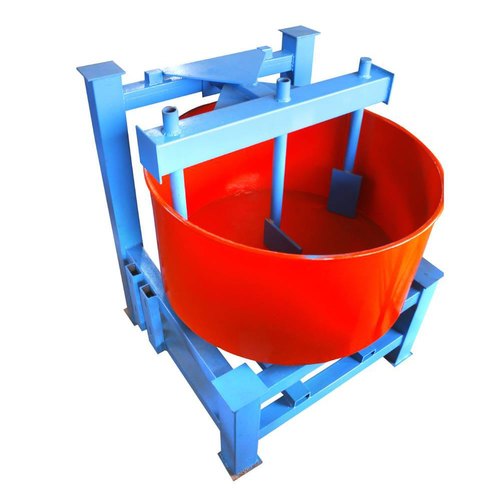

Pan Type Concrete Mixers

Pan type mixers consists a circular pan in which concrete is mixed. The mixing is done by blades which are arranged in star shape inside the pan. There are two types of pan mixers are available. In one case, the circular pan is constant and only star blades rotate about vertical axis of pan. In the other case, circular pan rotates while the blades are at static position. But in both cases, the mixing is efficient and concrete mixture is collected through central hole provided in the pan.

The rotating star blades contains special blades called scrapper blades which will make concrete not to stick to the pan. The blades can also be adjusted in height so, there is no room for concrete to store in the pan. We can say among the all types of batch mixers pan type mixer are more efficient.